Ultrasonic Cleaners - Overview

The ultrasonic cleaners offered by Greco Cleaning Systems are the product of over 50 years of custom engineering

experience and technical expertise. We include only the highest quality sweep frequency ultrasonic components in

systems that are expertly designed and built in the USA with particular attention to durability and ease of use.

We offer free-standing ultrasonic cleaning tanks as well as multi-station cleaning bench configurations. Because

we know that no two cleaning applications are exactly alike, we also offer custom-designed ultrasonic cleaners,

built to address each of our customer's unique cleaning requirements.

We also provide rinse water purifying equipment that will close loop your rinse stations and provide clean,

deionized water to your final rinse.

Systems are available in manually-operated or programmable configurations.

Whether you require a simple ultrasonic cleaner or an automated cleaning bench, we will be pleased to analyze every

aspect of your application and provide you with the most cost-effective solution to your cleaning problem.

Standard Ultrasonic Cleaning Tanks

The standard batch tank is the simplest form of ultrasonic cleaner. It consists of an ultrasonic

generator, also referred to as a power supply, and a transducerized cleaning tank. The transducerized tank is

constructed of stainless steel, with the transducer elements permanently bonded to the bottom of the tank. The ultrasonic energy is directed upward through the tank.

Standard models are available in the sizes ranging from

10" x 12" x 10" deep to 48" X 24" x 20" deep.

They include heated tanks and sweep frequency generators. All systems are available in 40-kHz and 25-kHz, with or

without stands, work rests, and particle filtration systems. Smaller systems are also available in 80-kHz, 120-kHz,

and 170-kHz.

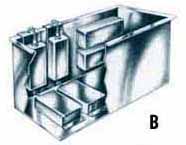

Custom Ultrasonic Cleaners

When the part size or configuration requires a special-sized tank, we offer

custom-designed ultrasonic cleaners. Greco Cleaning Systems employs immersible transducers, (Diagram B).

An immersible transducer is a hermetically sealed stainless steel container which contains a number of

transducer elements. These transducers offer the major advantage of versatility in system design. The custom cleaning

tank can be nearly any size that is appropriate to the application, and the ultrasonic transducers can be mounted on

the bottom or side of the tank to direct and concentrate the ultrasonic energy where it is needed most.

The Complete Cleaning Process

Most cleaning applications require that the part be rinsed and dried after cleaning. A typical cleaning line

consists of one cleaning tank, followed by one to three rinse tanks, and a dryer. These stations can either be configured as

individual cleaning, rinsing, and drying systems, or in a consolidated cleaning bench.

Individual Stations

Free-standing ultrasonic cleaners, rinse tanks and hot air dryers may be placed in line to

create the complete cleaning process. Drip guards are installed between stations to keep liquid in the tanks.

This approach is the most economical and offers the most versatility. If the cleaning process changes at some point in the future, tanks can be

added or moved to accommodate the new process.

Consolidated Bench Construction

Greco cleaning benches offer several advantages over individual stations. Cleaning, rinsing and drying stations are

built into a stainless steel frame and wired to a common electrical panel so that the electrical portion of the

installation is reduced to one connection. All electrical components are connected to a recessed control panel on the front of the bench. Water inlets and outlets

on each station are connected to common feed and drain manifolds to further simplify the installation. Access panels on

the front of the bench make it easy to perform routine maintenance tasks, and a removable stainless steel counter top

with a drip-proof lip simplify tank replacement if it should ever be necessary.

[Ultrasonic Batch Tank - Custom]

Cleaning Benches for Cellular Manufacturers

Our cbc-style cleaning benches are designed specifically for cellular manufacturing operations and

small parts processing. they can be installed adjacent to the manufacturing process or mounted on casters

for complete portability. these cleaning systems are available in several configurations, all designed to

maximize efficiency and minimize floor space. they are offered with single or multiple rinse stations and

can be paired with our lab style hot air dryer, modular hot air dryer, or a centrifugal spin dryer.

standard compartment sizes are 10” x 12” x 10” deep, 12” x 16” x 12”, and 16" x 20" x 16 deep. as always

with Greco cleaning systems, custom sizes and configurations are also available, as programmable lift systems

and rinse water deionizers.

Automation

User-friendly, programmable material handling systems are available for all standard and

custom cleaning benches. The automation system is programmed to lift the part from a load table, process it

through the precise cleaning, rinsing and drying stages, and drop it off at an unload table - ensuring process

consistency and leaving no room for human error.

Closed-Loop/Deionized Water Rinsing

Rinse water deionizing systems, also known as Rinse Purifiers, are designed to eliminate the need to send rinse water

to drain. These systems connect to the final rinse station(s) and circulate the rinse water through disposable treatment media;

removing both organic and inorganic contaminants. By continuously removing soap, contaminants, and minerals from the water and

returning pure deionized water to the rinse station, these recycling systems ensure that the final rinse station produces

ultra-clean parts that can be dried spot-free.